Zakłady Automatyki

Rotametr Sp. z o.o.- +48 32 331 11 11

biuro@rotametr.com.pl

Metal rotameters of KM, KM1G, KM2G, KME types

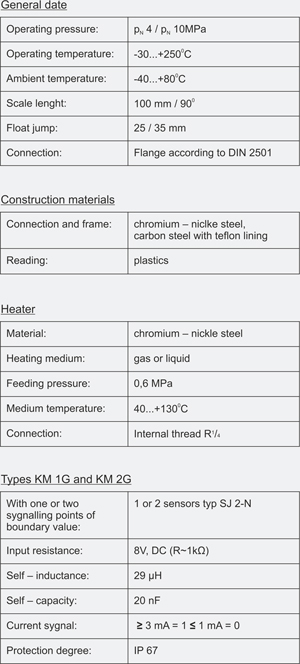

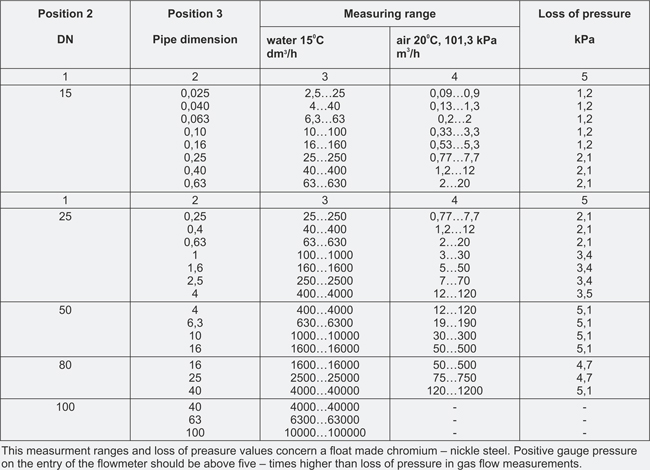

Float flowmeters are designed for liquid or gas volume measurment or as well as for mass measurment in closed conduit. The measuring set is put into the conduit. Rise of rotameter’s float by liquid or gas flowing up from below above the beginning of the scale is a measurement of liquid or gas volume. Float indication is transmited by magnetic clutch. Flowmeters are made of mechanics and chemical resistant materials.

Construction

In a standard version flowmeters are entirely made of chromium – nickle steel, which is chemical resistant for most substances in chemical industry. The steel can be also used to apply in food industry.

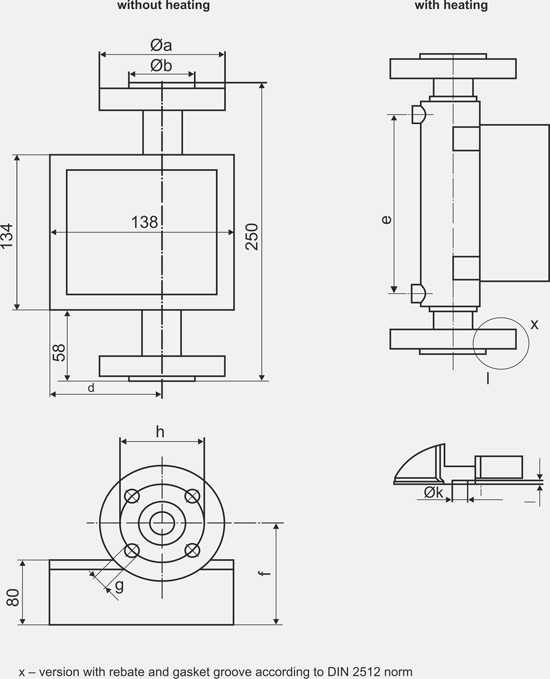

The flowmeter can have a built-in heating jacket. A heating jacket is a chamber with contact terminals. It enables heating of frame flowmeter by gas or liquid heating medium. Such a solution is being used as counteraction to freezing of the liquid measured in the flowmeter.

In some circumstances the flowmeter is being equipped with a vibration damper when used to measurments of flows of gas. Vertical float oscillations are caused by characteristic of meter circuit.

In case of some ferromagnetic particles found in measured flow the flowmeter may include a special kind of a magnet on which the particles settle. It presents them to settle on the float. The magnet, which is a part of a magnetic clutch is situated inside the float. The errors of measurments can be caused by ferromagnetic particles settled on the float.

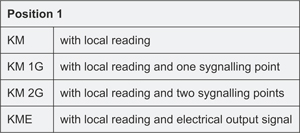

Standard versions of flowmeters

KM - with local reading

KM 1G - with local reading and one point signalling

KM 2G - with local reading and two points signalling

KME - with local reading and electrical output signal

Accuracy of reading

Flowmeters are calibrated by using verifing measurment instruments. In a standard version is 2,5 accuracy class guaranteed. The accuracy class can be improved when demanded. Accuracy class is characterized according to the PN-85/M-42371 norm.

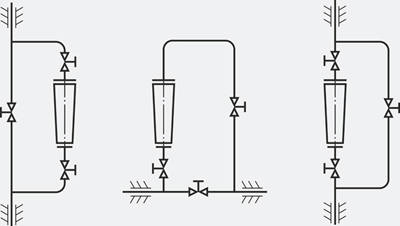

Installation

- The flowmeter should be installed vertically. Acceptable deviation for vertical is 20.

- Recommended to install side conduits (Pic. 1). It enables replacement of the flowmeter without process discontinue.

- The sediments can settle on the measuring elements in case of pollutions of some mediums flown through the equipment. Use also solvent sediment agent.

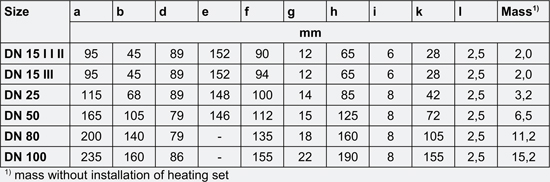

Main assembly dimensions of flowmeters

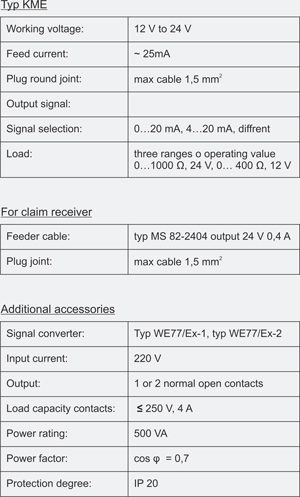

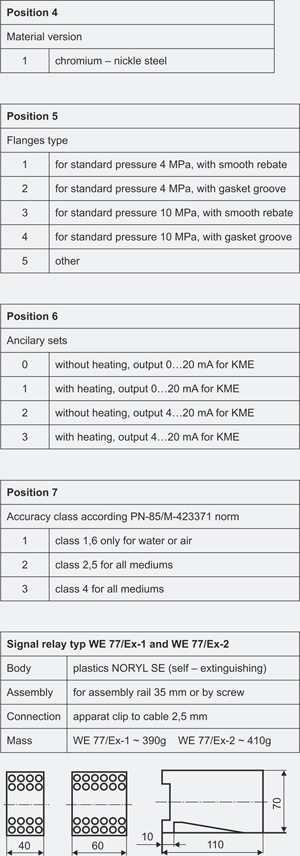

Specification

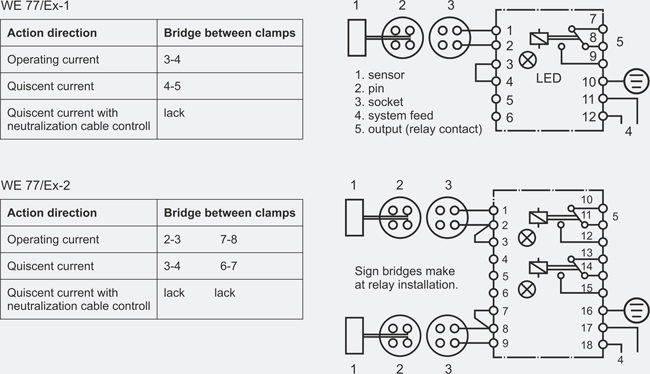

On the flowmeter’s frame the reading us shown. Independently of the local reading KM typ may be equipped with one or two point signalling of set boundary value. On the reading output the are current signals generate for each point. Current signals can be changed by the state of its fan-out contacts 500VA relay.

In a KME typ on the output reading there a current signal generated of the value of 0…20 mA or 4…20 mA or there is other signal according to the use’rs needs.

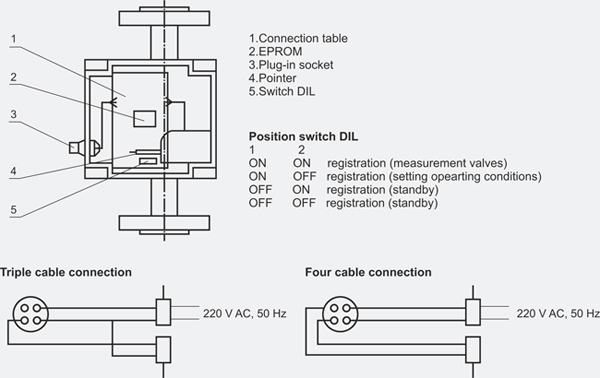

Scheme connection in KME flowmeter

send inquiry

send inquiry Download PDF

Download PDF