Zakłady Automatyki

Rotametr Sp. z o.o.- +48 32 331 11 11

biuro@rotametr.com.pl

Fuel sets

Fuel sets are designed for precise measurement of fuel consumption by combustion engine with self – ignition or spark ignition, which realizes drive of vehicles, machines, stationary equipment etc.

As a result of their use, consumers obtain information about real fuel consumption of the engine.

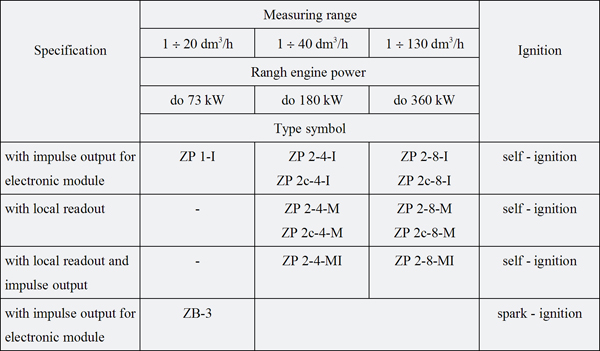

Fuel sets designed for compression – ignition engine are produced in many versions, which are designed for different types of engines and operating conditions. When matching characteristic of the feed system (e.g. lack of fuel return), types engine, fuel consumption and types injection system must be taken into consideration.

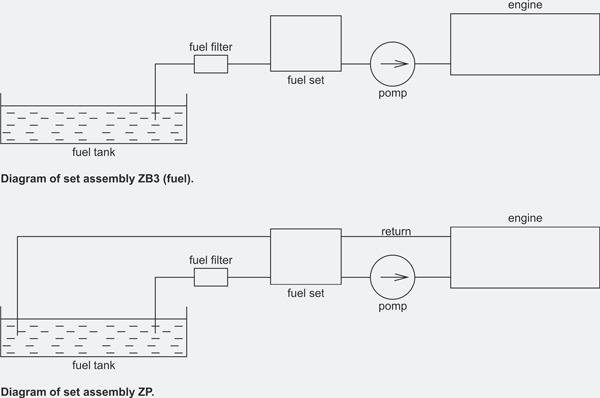

Depending on characteristic, build set in system can be different from general diagram. Invariable condition is included sets into line of suction in front of feed pump. Sometimes, in some fuel systems, besides fundamental measuring unit, heat exchanger must be installed. It concerns engines, which are equipped with injection units and in particular engine type of Cummins with injection system PT. Then part of delivery is included in heat exchanger.

Fuel sets designed for spark ignition (petrol engine) – symbol ZB-3 – are produced in one version and they can be applied for engines, which have maximum fuel consumption – 30 dm3/h.

Top class volumetric flowmeters are applied in fundamental flow measurement in showed units. Accuracy of reading of flowmeters is ±1% and accuracy of fuel sets ±1,5% (excluding the influence of temperature).

Value of fuel consumption is recorded by electronic module (e.g. MOTOGRAF) on the basic of flowmeter signal – it concern manufactures with letter “I” – and can be available in fixed form and mode (e.g. in display screen or printout). Value of fuel consumption is measured on a mechanical meter in manufactures with letter "M".

Fuel sets are guarded against undesirable interference. Electronic system records attempted interferences and moreover mechanical leaden seal protect access of parts of set – this concern sets of type "I". Mechanical leaden seal guard products of type "M".

Resistances of fuel flow in suction line increasing circa 0,02MPa for maximum flow in the range after installation of fuel set.

Assembly of fuel set is not difficult and the user can do it himself. However it must be done carefully to secure ideal tightness of all connections.

This is general diagram connections:

Types of fuel sets

Fuel sets do not require regulation after assembly and during normal operation. Periodically necessary filters should be exchanged. Detailed technical data is to be found in technical instructions, which are joined to products.

Practical application fuel sets:

ZP1 - delivery trucks,

ZP2 - construction equipments, road – making plants, heavy working machines, generating sets, motor trucks, etc.,

ZP2c - machines and units do., which have compression – ignition engine by Cummins with injection unit.

send inquiry

send inquiry Download PDF

Download PDF