Zakłady Automatyki

Rotametr Sp. z o.o.- +48 32 331 11 11

biuro@rotametr.com.pl

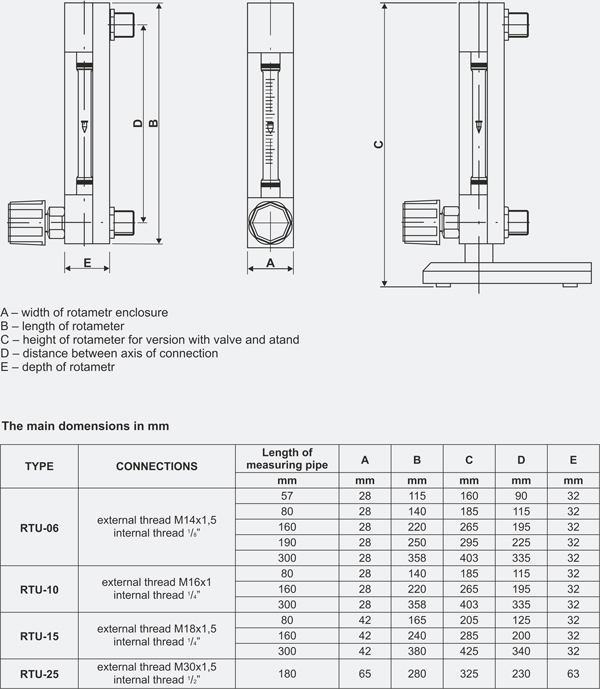

Boarding rotameter RTU type

The rotameters in boarding enclosure are designed for volume or mass flux measurement of gases and liquids in experimental, laboratory and industrial installations.

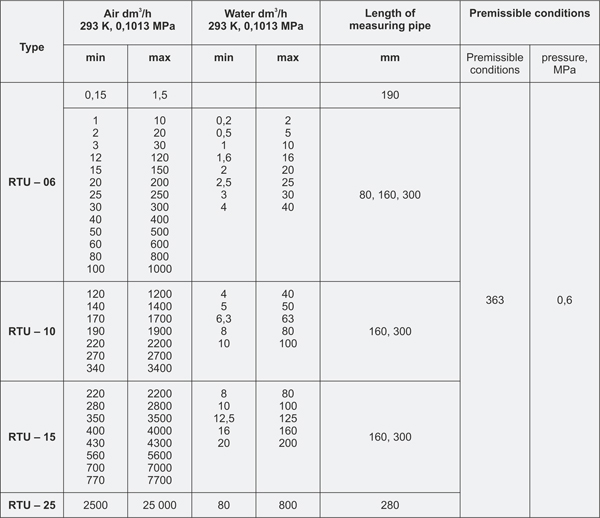

Exemplary measuring ranges

Accuracy of reading

The standard accuracy class is 2,5 according with PN-85/M-42371. On demand there is possible to execute the rotameter in higher accuracy class with calibration certificate from our laboratory, Weights and Measures Office or from Accredited Laboratory.

Installation directions

- The rotameter should be install in vertical position. The permissible devotion: 1.

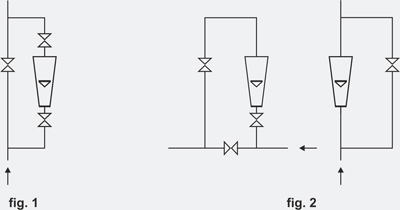

- In all types of rotameters the most profitable is ( in case of industrial rotameters it is necessary ) shount of rotameters (fig.1). It makes possible to exchange rotameter without the interruption in technological process. The detour valve in closed condition must be completely tight.

- The rotameter’s stresses and vibrations are not allowed. In industrial constructions it is necessary ( in front of and behind of rotameter ) to join the pipeline with supporting structure and installing the elastic parts in adjoining segments.

- For rotameter reading we used the biggest dimension of float. Very often it is the upper edge of float. In reading time the float has to assume a steady position without vertical osscilation. The flux of fluid can not contains the gas bubbles.

- Pollutants which flows through the rotameter creating the sediments on measuring elements so it is necessary disassemble the rotameter and flush it by dissolving substances. If the user is not able to clean up the rotameter there is possible to clean the rotamater by producent. The sediments in rotameter causes falsility measurements.

- The strong blows of floats by buffer can cause breakage of glass pipe. We can avoid this situation by installing additional cut-off valve (fig.2). In periods, in which occur strong changes of flux the cut-off valve should be open. After fixing of flux the cut-off valve has to be closed and the rotameter indication should be read.

- The rotameter which works in higher temperature should be protected against sudden cooling down for example treated by cold water.

send inquiry

send inquiry Download PDF

Download PDF